Doing It Better #6: Challenges To Be Expected / Persistence Towards Vision

Hardware

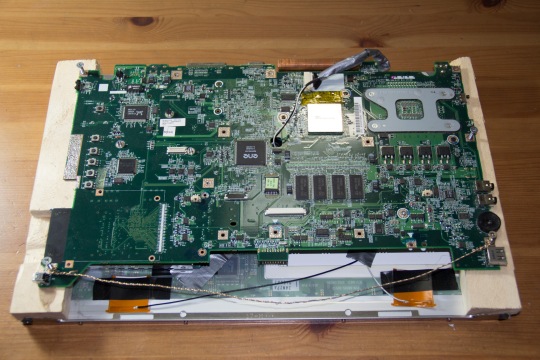

To be forewarned is to be forearmed. The first goal of this project is to effectively repurpose old laptop hardware into a digital picture frame, and improve on the quality of conventional frames. This project requires very tight cooperation between hardware and software, both being used in ways which they were not intended to.

Coming up are lists of anticipated challenges in both categories, which will have to be overcome in the final design. Although I do not mean these to be anywhere near comprehensive, they ought to serve as a guide in the design phase.

Frame Options

The following is a broad overview of the thought process employed in choosing a frame design and integrating the hardware into it.

- Taking the laptop apart should be relatively straightforward, but mounting the motherboard and components behind the screen, and the screen to the frame, will require extensive creativity.

- Creating a finished-looking product using only repurposed parts, and laying out all the components to fit inside a restricted area, will be a challenge.

- The following options exist for finding and/or designing a frame adequate in appearance and dimensions for the screen and components.

-

- Measure the frame and prepare exact dimension specifications, and get a décor shop to custom design a frame. After investigating, it seems the cost would likely be prohibitive.

- [décor shop custom frame design utility]

- Ikea’s website lists a “Ribba” shadow-box frame, a deep frame which would allow the hardware to fit behind the screen. The dimensions are too large, but a mat board could solve this.

- [Ikea ribba frame product picture and webpage]

- A woodworking friend could custom build a frame using a very simple design, allowing for exact dimensions to fit the screen, plus an appropriate depth for all the hardware to fit.

- With the right tools, enough time, and some wood, nails, and varnish, I could cut out my own frame exactly as needed, and design and finish it to taste.

- The frame will have to be modified significantly in one corner for cooling, and holes carved out for ports. I intend to use my Dremel tool with a wood-cutting disk. The CPU fan is located in one corner of the board, so I would have to carve one intake and exhaust vent. Ideally an USB port and the SD card slot would line up with the frame, so that customers could plug in such devices without unmounting the frame. The DVD drive could possibly have a slot, but its 2014 so that will probably get cut.

There are many reasons why laptops are so well suited to building digital photo frames, but they also have certain disadvantages. Hardware will be tackled first, so the following is a list of pros and cons concerning the use of laptop hardware.

Pros:

- Laptops are meant to be portable and compact, as such both the screen and components are thin and lightweight.

- The system is meant for general purpose business computing, which calls for a very powerful system.

- A laptop is lathered with ports and connectivity that are requirements for a computer, but also ideal for a photo frame.

- USB ports and an SD card slot are present around the motherboard’s perimeter for convenient photo import.

- Once configured, integrated WiFi allows the frame to always be connected online, and thus be updated offsite.

- integrated audio and VGA connectivity can be used to run projectors, and act as a media hub for a sound system.

[laptop port layout overhead diagram]

Although not all of these are features that the average user would take advantage of, they drastically increase the product’s potential and make it super interesting for geeks who want to go beyond its intended purpose.

Cons:

- High end laptop hardware generates significantly more heat than purpose built frame hardware, requiring loud active cooling fans.

- Because the frame has no buttons, it will make initial setup harder for people who are not technologically inclined.

Some of the usability issues will be addressed in software using special tools, and the complexity and versatility caused by laptop hardware allows this frame to go above and beyond what typical frames are capable of.

Software

Hardware is only half the battle. The second goal of this project is to improve drastically upon the horrendous custom firmwares typically installed on digital photo frames, and make up for some shortcomings in the hardware. The adaptability of dedicated laptop hardware combined with the versatility of available software and the possibility of programming, means that the possibilities are endless.

[terrible picture frame software interface]

The frame will most likely have no buttons, making initial configuration and photo upload problematic. All the tools are available to operate the frame remotely and button-free, and do so in a way that is both more user friendly and sophisticated than conventional frames.

Software Options

The following are some options considered in developing a user interface and a means of controlling the frame, uploading pictures, displaying a slideshow, and performing other miscellaneous tasks.

- Hire a friend to write a custom remote slideshow software running over Windows, that would update its own picture database remotely and offer a user friendly interface.

- Learn a graphical programming language with the express purpose of developing my own custom solution to displaying and configuring the slideshow.

- Every tool possibly needed is included in Windows itself, so why not adapt these to our purposes, and simplify the development by avoiding writing custom code.

Required Features

Selecting the last option, the core operating system would be Windows 8.1, the latest and greatest, and would have to be cracked for the time being because investing over $100 per frame for software is impossible in my position. Basic capabilities required by the frame are as follows. [windows 8.1 screenshot]

- Ability to seamlessly upload pictures to the frame’s hard drive, using some sort of network synchronization.

- Have a slideshow always running and automatically keeping itself up to date from this sync folder.

- Ability to remotely control the frame from another system on the network, or using a phone with a special application.

- Being able to perform any actions in Windows, such as pulling up a webpage or YouTube video in a browser.

- Some sort of maintenance such as an occasional Windows reset, scheduled shutdown and startup for the night

- A trigger to reenable the slideshow, hiding all windows, once the computer is idle for a certain time.

Implementation Details

Through Windows alone, I have proposed solutions for ALL OF THESE. Only initial configuration will require a USB mouse and keyboard, so that one can connect it to WIFI. After this, the frame will only require a single power cable.

- The slideshow will simply be the Windows desktop background in timed slideshow mode, and will be sourced from a folder in which the “Select All” option has been set. In this way, any new pictures will be added to the slideshow as soon as they are uploaded. Options exist to randomize the slideshow, fade between pictures, and change the interval length.

- [windows desktop background selection]

- Images will be uploaded to the frame over the internet via SkyDrive to the slideshow’s source folder, which will be marked “Make Available Offline” so that the pictures are saved permanently to the hard drive. SkyDrive is integrated into windows and can be accessed via one’s Hotmail account, and on the same network LAN sync allows rapid uploading using no internet bandwidth.

- [skydrive online interface screenshot]

- Windows time-based Scheduled Tasks will be used to shut down and start up the computer routinely, and to hide open windows the user has opened after a certain idle period.

- [windows scheduled task creation interface]

- A phone can act as a remote control on steroids; the frame will be preconfigured with a Remote Touchpad server, which any phone on the local network can connect to and act as keyboard and mouse.

- [remote touchpad android application screenshot]

- Remote desktop for configuration or general usage purposes will be possible either through Windows RDC, or some third party solution.

- [remote desktop interface plus session screenshot]

Using this software setup, the digital picture frame will be completely autonomous and feature complete, and should also be quite user friendly. Once initial setup is complete, the system will run continuously and be updateable and usable without ever touching it.

Once the first system is completely configured, a golden master image of the hard drive will be captured with a program such as CloneZilla, and this image will be copied to the hard drives of one frame to the next, so that each one comes with software installed out of the box.

[clonezilla screenshot]